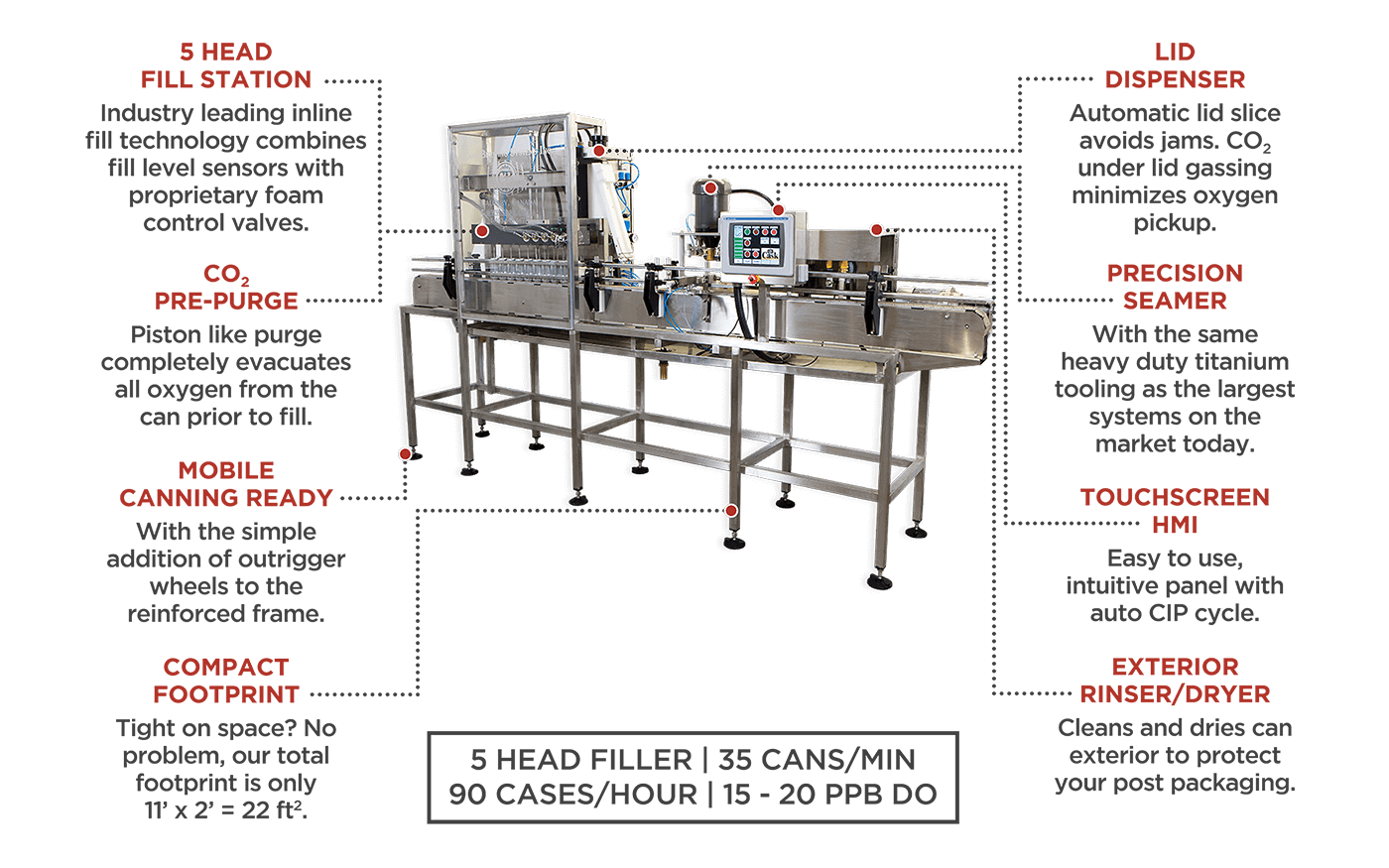

35-CPM Conveyer-Driven Automated Canning System

The automated canning system is designed to fill and seam 35 cans per minute (measured with 12 oz/355ml cans) or 90 cases per hour. The system consists of a core conveyor with motor drive, a five head filler, a can lid dispenser, and a heavy duty can seamer all mounted on a stainless steel frame.

Our current V4.2 design will handle multiple can heights of the same diameter with minimal change over time (ie. 12 oz/355 ml and 16 oz/473 ml cans)

Service & Support

After your initial 2 to 3 day setup and training, our dedicated Support Department is standing by to answer your call or email.

We will troubleshoot with you remotely, dispatch replacement parts overnight, and if required will send one of our qualified Technicians for a site visit.

![]()

Industry Leading Fill Tech

Our proprietary foam creation valves result in some of the lowest oxygen pickup numbers in the industry. Our customers have been able to achieve as low as

15 to 20 ppb DO pickup.

Don't let dissolved oxygen ruin your unique craft flavours!

Built to Last

The first ACS V1.0 was installed in 2002 and is still running strong almost two decades and more than 10 million cans later.

Our reliable design is time tested with proven reliability that your craft beverage business can depend on.

ACS V4.2 Features

- System infeed provided by Cask shaker table or Cask Automated Depal.

- Modularity for future expansion: mirrored design available for efficient side-by-side dual system operation.

- Simple change over between multiple can heights and widths!

- Adjustable fill level sensors make precise, repeatable fills across all 5 fill heads.

- Manual and automated post-packaging options available (six pack or PakTech® can carrier)

- Shrink sleeve and pressure sensitive wrap around label options available.

- Electrical certifications: ETL (Canada/US) and CE compliant (Europe)

![]()

Interested in more information or a quotation?

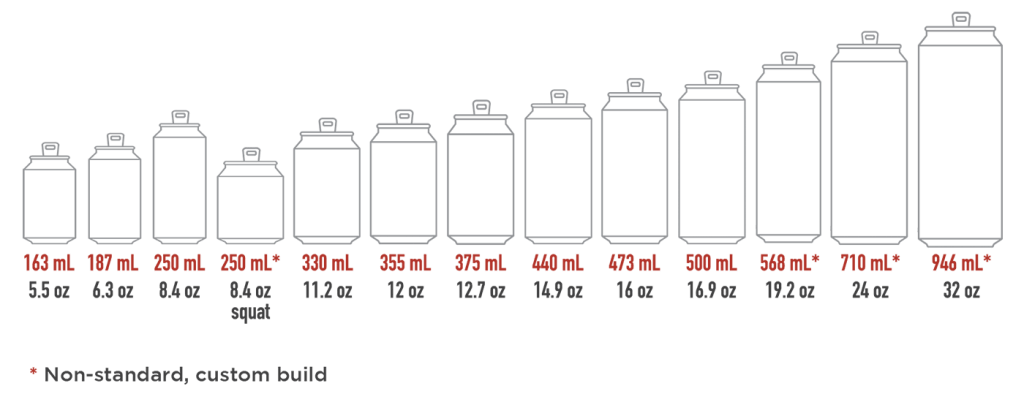

Multiple Can Sizes

Over the decade and a half that Cask has been manufacturing the Automated Canning System, we have built an ACS for nearly every can size out there. Change over between different can dimensions is a snap, requiring only a few simple tools and less than 30 minutes.

Interested in large 24 oz / 710 mL or 32 oz / 946 mL cans? Cask has also developed the “Big Fat ACS” specifically for this purpose.

Note: the ACS can only be configured for multiple can heights of a single can diameter.

Outgrown your existing ACS?

ACS V4.2 Specifications

| Power | Three Phase, 208 - 240VAC at 15A, 50/60 Hz |

| CO2 | 25 psi from plant system connected to matching with 3/8" barbed fitting |

| Air | Filler & Seamer: 5 cfm at 90 psi Optional Air Dryer: 12 cfm at 30 psi Total System: 17 cfm at 90 psi Compressor c/w refrigerated dryer and autofloat drain |

| Water | 1/2" hot water line (Clean In Place CIP) 1/2" cold water line |

| Beer | Temperature: 32 - 35.6 F (0 to 2C) Carbonation: 2.4 to 2.9 volumes CO2 (4.6 to 5.6 g/L CO2) |