BUILDING YOUR

CAN PROGRAM STRATEGY

Craft beverage makers can make smart planning decisions now to ensure they are building a can program that is right for them by considering key factors:

CHALLENGE

Craft breweries have often had to source can supply from multiple vendors and manufacturers over the last several years, making it difficult to guarantee quality or plan ahead strategically.

OPPORTUNITY

Craft breweries are in a great position to critically assess their can program for the upcoming year and protect themselves against market factors like future supply shortages.

DESIGN ECONOMICS & MOQs

Deciding on the packaging mix that is right for your brewery can help you maintain better margins. Breweries like SingleSpeed Brewing use a combination strategy of printed cans for their core SKUs, and a base printed can for limited releases that they label over top of for flexibility. Smaller breweries still largely do not have the volumes to access Printed cans or Brite cans, so finding the right partner for smaller volume options is critical, be it digitally printed cans or shrink sleeved cans.

PRINTED

Photo: Wiseacre Brewing Co

Printed cans are the most economical choice for breweries with volumes of 25 pallets for their core brands.

MOQ: 1 Truck (25 Pallets)

Lead Time: 6-8 weeks from Artwork

BRITE

Photo: SingleSpeed Brewing

Bringing a labeler in-house is a cost-effective way to give breweries absolute flexibility and reduce lead times.

MOQ: 1-25 Pallets

Lead Time: 2 weeks from Order

DIGITAL PRINT

Photo: Hinterkopf

Some companies offer Digitally Printed cans at lower MOQs that are more environmentally friendly than shrink sleeves.

MOQ: 1 Pallet

Lead Time: 4 weeks from Artwork

1 Truck MOQs for Ball Printed cans is back!

Want to discuss getting into smaller volume Printed cans?

QUALITY & SINGLE-SOURCE SUPPLY

Why does having a single source for can & lids matter? Securing can and lid supply from a single high-quality manufacturer is one of the best ways to avoid painful seamer issues. Can manufacturers each have proprietary product specifications. Every body/end combo can require unique setup and tooling. Knowing where your can supply comes from is critical. Check out variances across 3D scans of B64 lids:

VENDOR PARTNERSHIP

Choosing the right vendor partnership is equally as important as ensuring that you have quality supply. Vendors can offer terms that make sense for the size of your business, forecasting and planning support and contracted supply.

PROTECTION

Vendors that keep inventory can help protect customers against future shortages. Also ask, does your vendor have contracted supply with their manufacturer?

SUPPORT

Account managers can offer personalized service and support. You want to make sure your vendor can advise you on key market insights and help you plan.

QUALITY

Distributors and Resellers may offer a variety of can and lid ends. Ensuring you're getting the same high-quality cans every time is critical for liner and seam security.

ALUMINUM PRICES & SUPPLY SHORTAGES

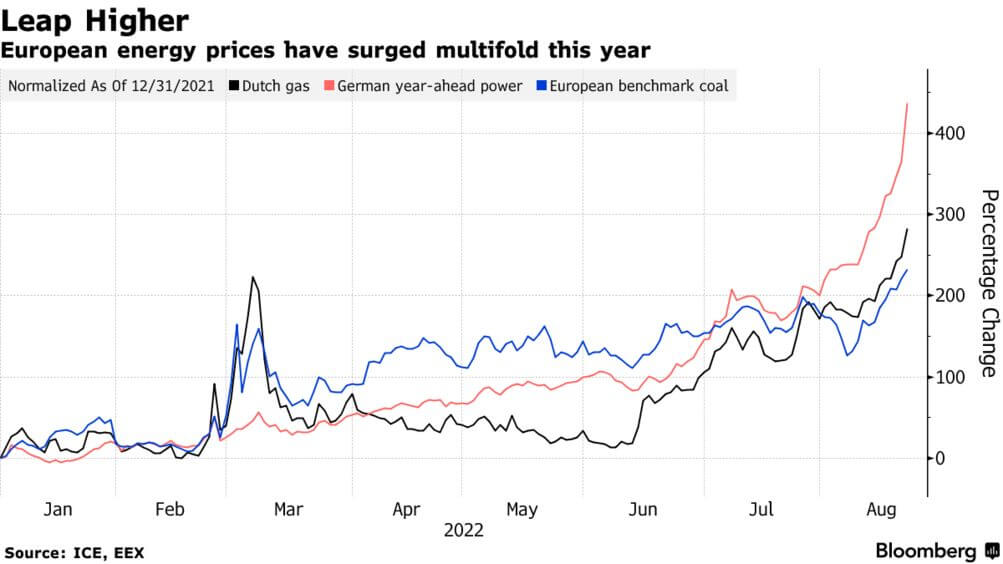

According to a recent article from Metal Miner, European aluminum production is at its lowest since the 1970s due to surging energy prices. Plants across Europe have drastically reduced production, some shutting down altogether.

Additionally, the industry will expect to see pricing increases of 15-20% for Aluminum cans at the start of the year. Planning now to ensure a secure supply of cans for the upcoming year is essential for craft breweries to keep margin and stay protected.