Already have a Cask ACS and your brewery is expanding?

Achieve 70-CPM with low incremental investment

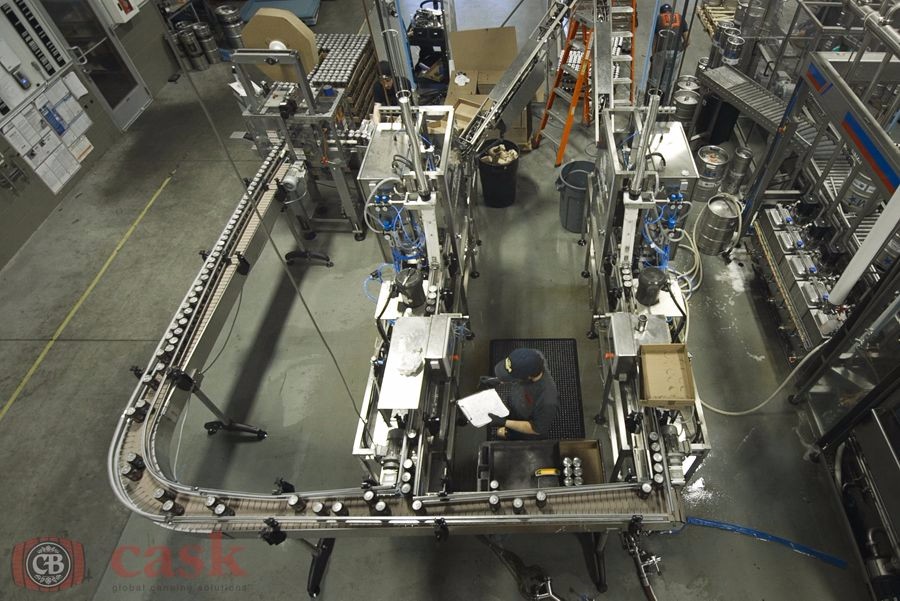

The Dual ACS can increase canning output dramatically. It can produce a reliable 70 cans per minute, or up to 175 cases per hour with two to three operators.

- Operational space of 15 by 20 feet.

- Cost effective and labour efficient.

- Handles multiple can heights.

- Available gravity fed can pre-rinser and depalletizer.

- Electronic production metrics.

New to canning? The Dual ACS has been replaced by our newest innovation released for production in 2015, the significantly more compact Cask ACS X2.

2 x 35-CPM Conveyer-Driven Automated Canning Systems

Each automated canning system is designed to fill and seam 35 cans per minute (12 oz/355ml). The machines can accommodate larger or smaller can sizes but only one can size per machine. (ie. 12 fl oz/355 ml or 16 fl oz/500 ml cans or 8.3 fl oz/250 ml cans).

Each system consists of a core conveyor with motor drive, a five head filler, a can lid dispenser, and a heavy duty can seamer all mounted on a stainless steel frame.

Package Into Printed Cans

Cask will help with the entire canning project from the initial concept to final production. Cask is the official supplier of Ball Corporation for the supply of printed aluminum cans to our customers.

Post Packaging

Post packaging products are available from third party suppliers for six pack rings, plastic carriers and cardboard boxes. Contact your sales representative for details.

Service and Support

To ensure long-term success of your canning project we understand how you need dependable follow up support. We are a dedicated, full-service supplier. Our knowledgeable staff offers preventative maintenance, quality control and repair guidance through onsite visits, toll-free telephone support and email.

Dual ACS at Perrin Brewing, Michigan