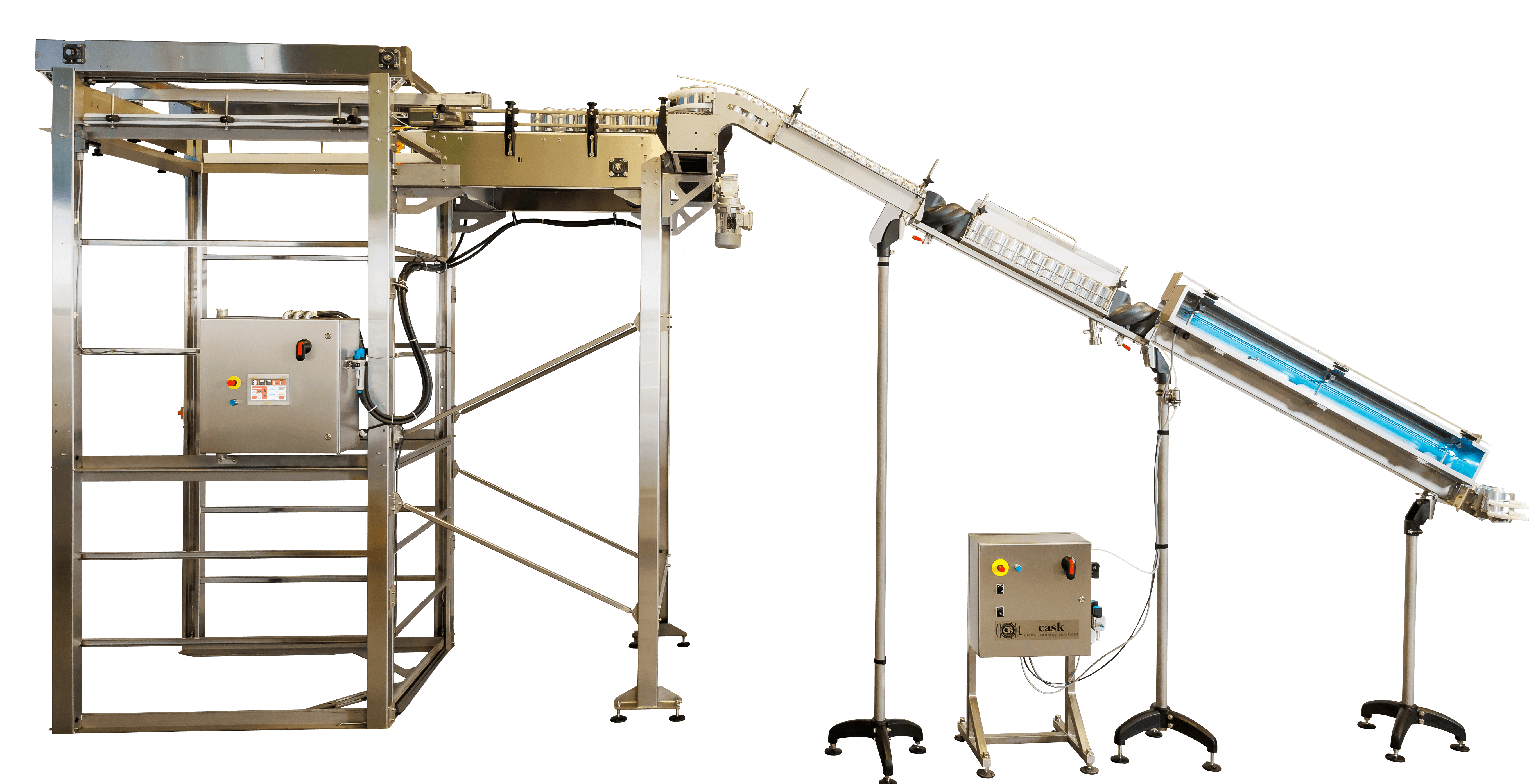

Complete Automated Infeed Solution

The Automated Depalletizer pairs with the 3D Printed Rinse Inverter that reduces can size changeover downtime to seconds. Add-on the UV-C & Ionized Air Treatment features to eliminate water usage and minimize Dissolved Oxygen pick-up during the rinsing process.

Want to discuss a right-fit solution for your space? Connect with the Cask team!

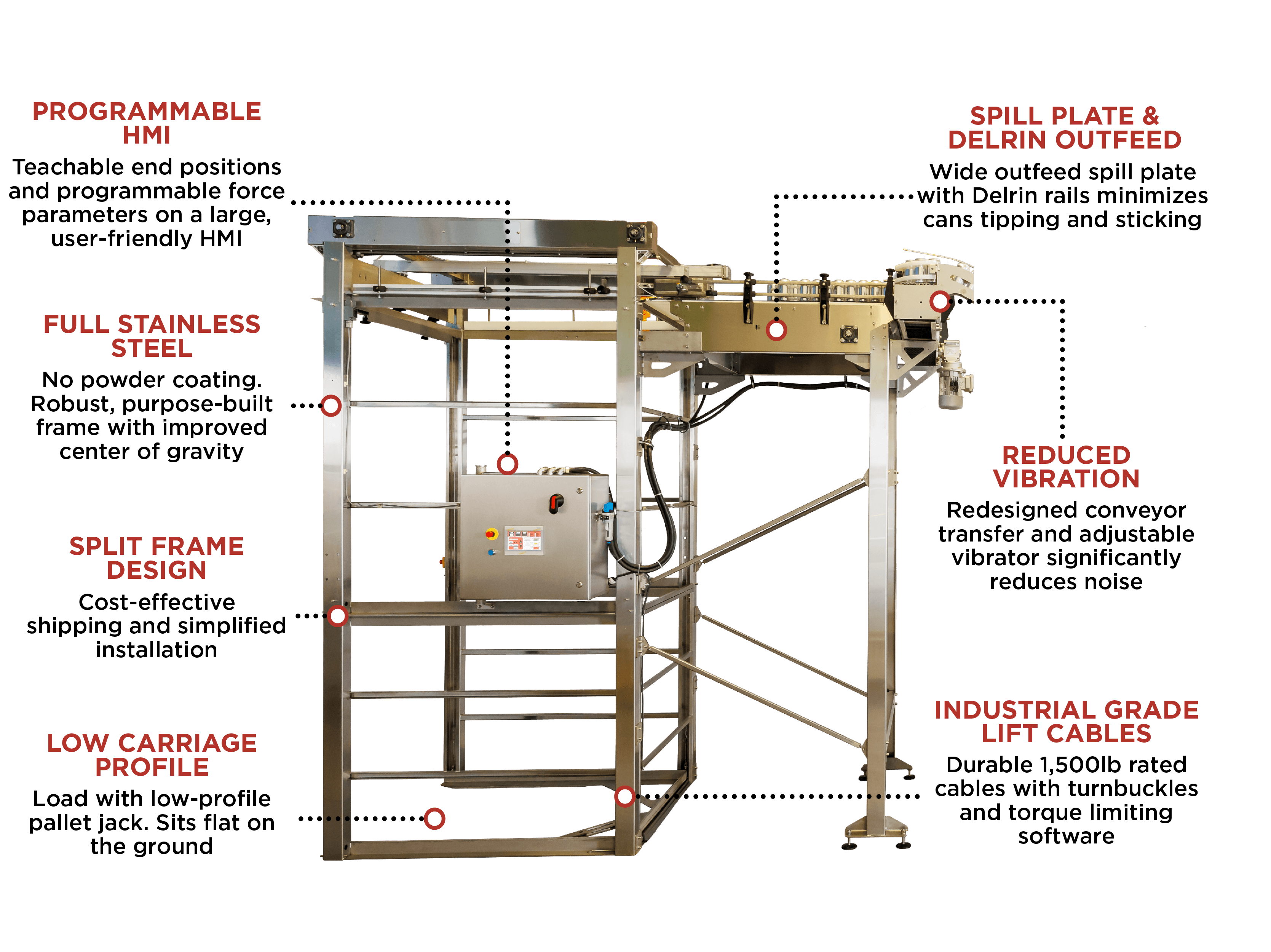

Automated Depalletizer Features

- Half-Height and Mobile Half-Height set up options available!

- Quick, tool-less can size changeovers

- Compatible with nearly all can sizes and pallet dimensions

- No pneumatics. Sweeper arm is force-sensing and operated by linear drive; Customizable frequency and force for optimal precision during sweeping

- 7” touchscreen HMI display for improved operator control

- Automated sub-routines assist initial set up, including initial tier sheet removal and height-sensor adjustments

- Collapsible frame for easy shipping and installation