Our role as craft beer’s micro-canning inventor stretches back to the late Nineties. But our history in craft beer reaches back to the early Eighties when we supplied brewhouses and tanks to the world’s first microbreweries and brew-on-premise (ever heard of them?) establishments around the world. Yes, way before “craft” beer was even a term. Since then we’ve carried out our unique form of canarchy by smashing the bottles-only glass ceiling and making the once scoffed-at aluminum can the package of choice for the planet’s most discerning beer makers.

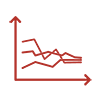

Standard, Slim or Sleek!

Cask canning lines accommodate numerous coffee-appropriate can sizes, in any Standard, Slim or Sleek formats ranging from 163mL/5.5oz to 568mL/19.2oz with minimal changeover time.

Inline Scale & Auto Reject

An inline scale provides onscreen trending of can weights to 2g accuracy, in real time. Get instant operator feedback for fill consistency and adjustments, with an auto reject arm that automatically purges out-of-spec cans onto a catch tray.

![]()

Industry Leading Fill Tech

Cask’s level-sensing probes ensure more consistent fills than other technology (timed filling systems, for example),to eliminate variables in brite tank head pressure or temperature that can lead to over- or under-filled cans.

Cask System Features for Craft Beer

- Proprietary foam creation valves deliver some of the lowest dissolved oxygen (DO) pickup in the micro-canning industry. Cask customers achieve as low as 15 to 20 ppb DO pickup. This provides maximum protection from flavor-crushing oxygen.

- Cask systems have level-sensing probes to ensure proper fills more consistently than other technologies such as timed filling systems. Timed systems can create variability in brite-tank head pressure or temperature during a canning run, which can result in over- or under-filled cans.

- Our ACS V5 and FleX2 canning systems have inline scales that provide onscreen trending of can weights to 2g accuracy, in real time. Get instant operator feedback for fill consistency and adjustments, with an auto reject arm that automatically purges out-of-spec cans onto a catch tray, allowing unparalleled quality control of your finished packaged product.

- Your canning line could accommodate any Slim, Sleek or Standard diameter can size on the market ranging from as small as 163mL/5.5oz to as large as 568mL/19.2oz. Change over time between multiple can heights can be as quick as 30 minutes, and just over an hour when changing between multiple diameters

- The ability to package multiple diameters allows versatility in co-packing with other craft beverages.

Interested in more information or a quotation?

Pre-Package Planning for Craft Beer

- Generally speaking any four ingredient beer you can brew is already can compatible!

- Any beer with exciting or non-standard ingredients (i.e. fruit) or more than typical beer ingredients must be compatibility tested. Comparability testing for sour beers is strongly recommended.

- Cask and Ball Corporation will work closely with you to ensure that your beer is ready for the mighty aluminum can. Ball chemists will test the corrosivity of your beer and look at total alcohol content, pH, free SO2, copper and dissolved oxygen (DO), and other factors. This comprehensive testing ensures your product will be shelf stable and remain the highest quality after canning.

Technical Requirements for Craft Beer Canning

- Pressurized brite tank to approx. 15 psi to feed the canning system.

- Beer temperature: 32 - 35.6 F (0 to 2C)

- Beer line length from brite to canning system: recommended at 15ft or less (the shorter the beer lines, the better your foam control)