![]()

Electric Cam Driven Seamer

Cask’s revolutionary automated canning system design pairs a cam-driven seamer with an electric stepper motor. Get increased seam integrity by the most consistent seam formation force, with significantly easier setup and maintenance compared to pneumatic seamers.

Inline Scale & Auto Reject

The ACS V5 automated canning system features an inline scale that provides immediate onscreen feedback, in real-time, which displays extremely accurate weights of cans that are accurate within two grams. This allows the line operator to make note of any inconsistencies and to make adjustments. Meanwhile, an auto-reject feature will purge cans from the line into a catch tray if they are too high or low in weight.

![]()

Industry Leading Fill Tech

Each of our automated canning systems features proprietary foam-creation valves which help deliver the lowest amounts of dissolved oxygen (DO) in the micro-canning industry. Many of our customers have reported DO pickup in the extremely low values of 15 to 20 parts per billion, ensuring flavor protection.

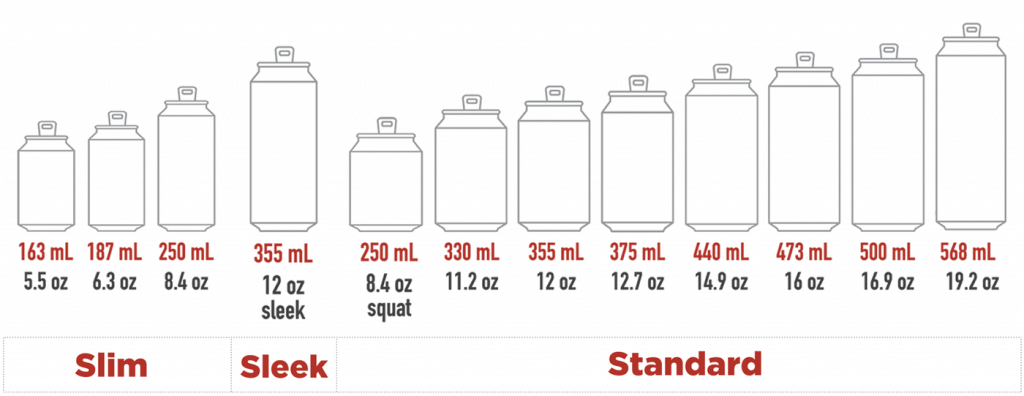

Incredible Packaging Flexibility

The Cask ACS V5 is the most flexible #MicroCanning system on the market, specifically engineered to allow one system to handle nearly all can heights, body diameters and end types. Change over between different can sizes is a snap, requiring less than 30 minutes.

Not Just Craft Beer

This is so much more than an automated beer canning system. The flexibility of ACS V5 and its nitro doser make it ideal for a number of other craft beverages, including wine, cider, cold brews, and more.

ACS V5 Specifications

| Power | Single Phase, 208 - 240VAC at 15A, 50/60 Hz |

| CO2 | 25 psi from plant system connected to matching with 3/8" barbed fitting |

| Air | Filler & Seamer: 3 cfm at 90 psi Standard Air Dryer: 12 cfm at 30 psi Total System: 15 cfm dry air at 90 psi Compressor c/w refrigerated dryer and autofloat drain |

| Water | 1/2" hot water line (Clean In Place CIP) 1/2" cold water line |

| Beer | Temperature: 32 - 35.6 F (0 to 2C) Carbonation: Up to 3.2 volumes CO2 |

ACS V5 Features

- 15% faster than previous ACS verions at 40 cans/minute or 100 cases/hour!

- Nitrogen doser ready for packaging of un-carbonated beverages and nitro-beers

- Exterior Can Rinser and Lid Dryer included as standard

- Time saving Recipe Memory saves fill settings for your entire beer/beverage lineup

- Can infeed - by shaker table or Cask Automated Depalletizer - requires just one operator

- Manual and automated post-packaging options available (six packs or PakTech® can carriers)

- Shrink sleeve and pressure sensitive wrap around label options available

- Highly compact footprint of just 11’ x 2’ = 22 square feet (3.4m x 6m = 2 square meters)

- Electrical certifications: ETL (Canada/US) and CE Compliant (Europe)

![]()