ABOUT

CASK DATA LABS

A lot of Craft Breweries have relied on packaged product over the last year-and-a-half, and many are already making products other than beer to generate new revenue streams. Hard seltzer added $344m in off-premise retail sales during Covid from April 2020-2021. Of those sales, 60% of growth is from new SKUs, according to Brewbound.

Cask Data Labs offers a tool for craft beverage makers looking for a carbonation benchmark as they develop new products or simply seek to gain insight into the market.

This multi-part series combines data and beverage experience stories to address the questions and curiosities we hear most frequently from craft beverage makers. In this series, we will cover:

CHALLENGE

Over 1/3 of Craft Breweries in the US already make products other than beer according to the Brewers Association.

Most small businesses don't have access to lab grade CO2 testing equipment, making it difficult to benchmark carbonation as they pilot new products in these fast-growing beverage categories. Lack of benchmarking data leads to misguided process and packaging requirements.

OUTCOME

Commercially available products analyzed never exceeded 2.8 vol CO2 in-can, while craft beverages from Cask customers packaged on our in-line atmospheric filler ranged from 1.9-3.3 vol in-can.

Carbonation plays a clear role in defining craft beyond the mass distributed seltzers and RTDs. However, consumer perception of carbonation was much higher than the reality of in-can results.

VOLUME 1: TESTING PRODUCTS YOU KNOW

COMMERCIAL LANDSCAPE

“Commercially available canned seltzers are typically carbonated to about 2.8 volumes - they should have some zip to them," says Joe Stange, Craft Beer & Brewing Industry Guide.

Most industry guides recommend hard seltzer makers carbonate their beverages to anywhere between 2.8-3.0 volumes of CO2, including Briess Malt & Ingredients Co., Vine Pair, First Key Consultants, and Craft Beer & Brewing Industry Guide.

After completing a wide array of beverage analysis we found that none of the commercial products tested were over 2.8 volumes in-can.

Mouthfeel and sweetness contrasted with carb level data of familiar products provided helpful explanations for beverage experience and flavor perception.

WHITE CLAW

2.31

Hard seltzers like White Claw with no added sugar don't require extra carbonation to offset any sweetness. The bubbles and fruity scents when you open the can allude to higher carb, but past the first sip the bubbles dissipate quickly and the zip overall is pretty mellow.

TRULY

2.48

Truly's Mango Lemonade tastes distinctly sweeter than the brand original, containing 1g of cane sugar and Stevia. The higher carb helps balance the sweetness and offer fizz that feels more fun and seasonal than their flagship products.

JACK DANIEL'S & COLA

2.61

Jack Daniel's ready-to-drink version of the bar classic Whiskey & Coke requires higher carbonation to balance the sugariness of the cola. The syrupiness of the bourbon is more flavor-forward, ensuring the fizz of the soda doesn't dominate mouthfeel.

PERRIER

2.68

Perrier has been the benchmark of fizz since their "Perrier, c'est fou!" or "Perrier, it is crazy!" ad campaign in the 60s. The mineral water is dry, adding to the perception of higher carbonation. But the bubbles stay on your tongue, without being so "crazy" that they travel up to your nose.

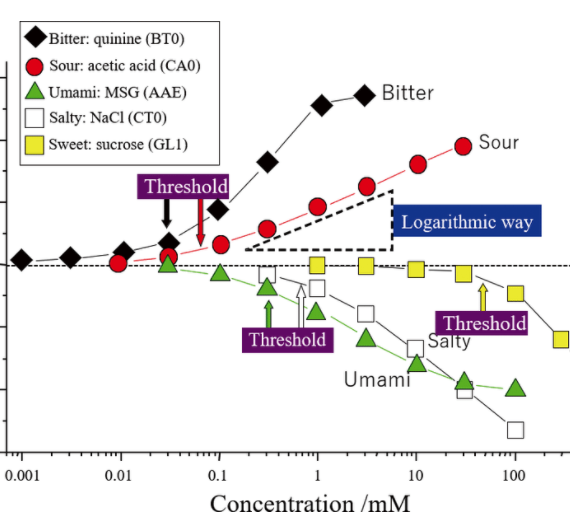

THRESHOLD OF PERCEPTION

Just like beer, fizzier non-beer beverages taste better than flat ones. However, it doesn’t have anything to do with the bubbles actually bursting in your mouth. The "taste" of carbonation we experience is activated by the enzyme Carbonic Anhydrase 4 (CA-IV) reacting with CO2 sending a sensory message to our brain that we are tasting something with some zip to it.

Taste though, is logarithmic. Past a certain threshold, we no longer perceive a beverage to be any more sour or fizzy. The good news is the standard brewing process and the right packaging set-up support your full ability to push the threshold of perceived fizziness.

VOLUME 2: DATA FROM THE CRAFT COMMUNITY

CARBING CRAFT

Next we analyzed a range of craft beverages from Cask customers, including hard seltzers, sparkling water, kombucha, RTD cocktails and sodas. Each of these customers produce more than one type of beverage as a way to diversify their revenue stream, engage with new audiences and create bandwidth in their business.

These craft beverages covered a wide range of carbonation from 1.9-3.3 vol CO2 in-can. With a carbonation benchmark established for products like White Claw and Jack Daniels & Cola, it became very apparent how much carbonation plays a distinct role in the "craft" part of the craft beverage equation.

BREAKWATER HARD SELTZER

3.32

Michigan-based Ore Dock Brewing Co. launched spin-off project Breakwater Hard Seltzer in 2019. Breakwater in-can CO2 averaged 3.3 vol CO2 across their core SKUs, significantly higher than the commercial hard seltzers - and it's noticeable. The zip lingers longer, the fruit flavors pop more, it's distinct from the macro-made seltzer readily available at big outlets.

HAPPY BELLY KOMBUCHA

2.00

The "taste" of carbonation we experience is activated by the enzyme Carbonic Anhydrase 4 (CA-IV) reacting with CO2. The reaction triggers a sensory message to the brain and we perceive what we're tasting to be sour. So while the kombucha is less carbonated, the lower pH actually triggers the same sour taste buds as higher carbed beverages and gives the perception of something more fizzy.

ANNEX ALE PROJECT & SODA MFG

2.68

Annex's product line-up includes craft beer, soda and RTD cocktails. Their natural ingredients make this Root Beer refreshingly spicy. When compared to the mouthfeel of Coca Cola, Coke is identifiably carbed at 3.1 to distract from the sugariness and flatter flavors, while Annex Sodas carbed to 2.7 give breathing room for pronounced flavors and guides mouthfeel through complex layers.

BREWING PROCESS

Every Brewer is familiar with the CO2 Volume Chart. Majority of Brite Tanks in North America are rated for 15 PSI, meaning even at low temperatures (30F/-1C), beverages would be carbonated up to a maximum 3.35 vol CO2. Given you should expect to lose 0.15-0.30 vol CO2 during the packaging process on any style of filler, ensuring your canning system can successfully package your product up to 3.3 vol CO2 will give you a wide range of flexibility to develop new products.

VOLUME 3: DO YOU NEED A COUNTER PRESSURE FILLER?

PACKAGING HIGH CARB

A lot of people have asked – don’t you need a counter pressure filler to can higher carbonated beverages? In short, the answer is no.

Cask introduced the first commercial-grade atmospheric filler 20 years ago with the mission of giving Craft Brewers access to a small, cost-effective packaging solution offering the same, if not better, quality as large commercial rotary fillers.

Cask's Filling Technology, which ensures product loss below 1% while still achieving shaken DO numbers below 20ppb on beer, is also what allows beverage makers to successfully package beverages over 3.3 vol CO2 in-can.

Here’s how we control the fill:

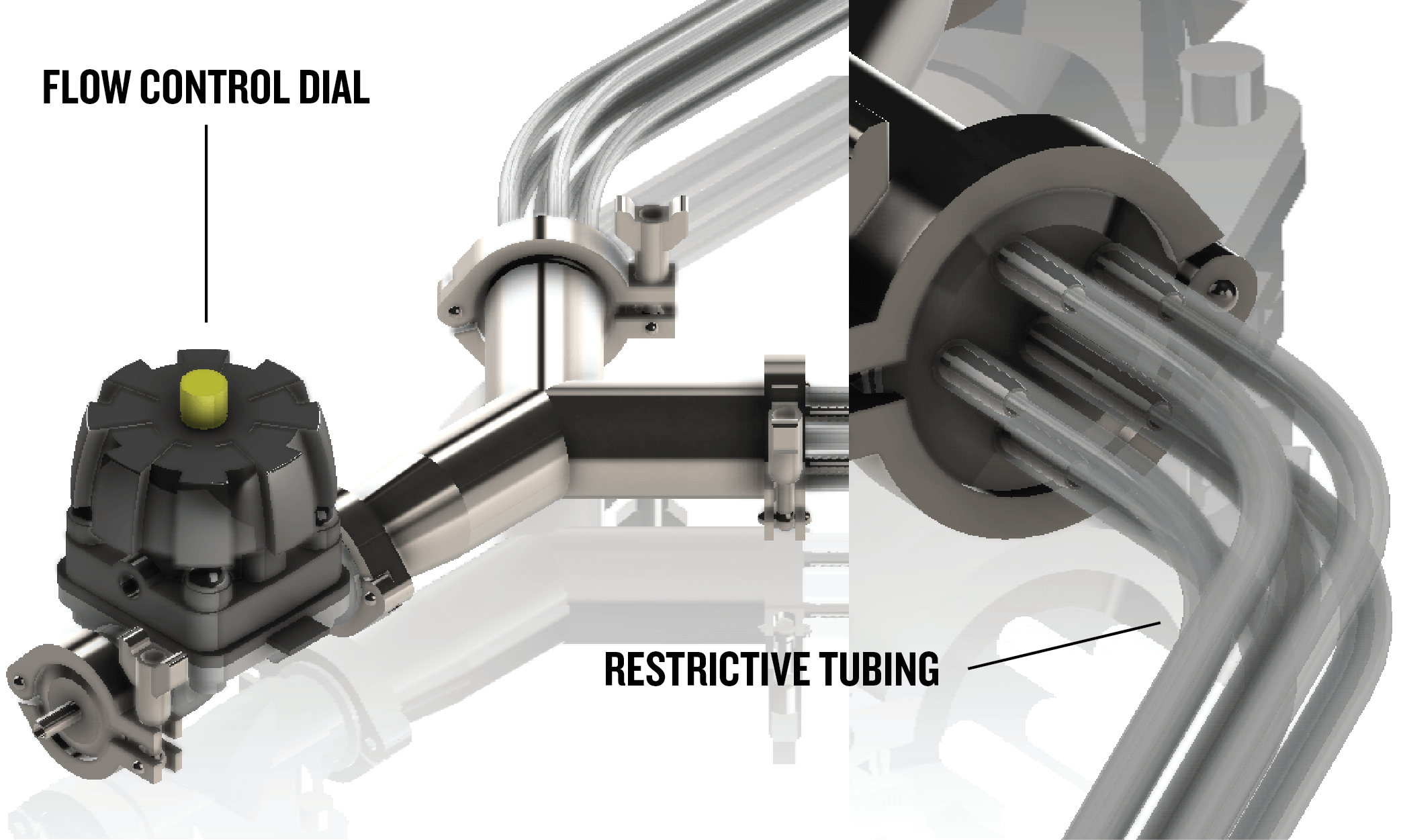

AT THE SUPPLY MANIFOLD

Restrictive Tubing and a Flow Control Dial on Cask Automated Canning Systems apply supply-side restrictions to ensure a steady, controlled flow of product to the filler. The physical restriction keeps carbonation in solution, stabilizing it on the way to the filling manifold where it is dispensed slower than even a standard draft system to minimize breakout and product loss.

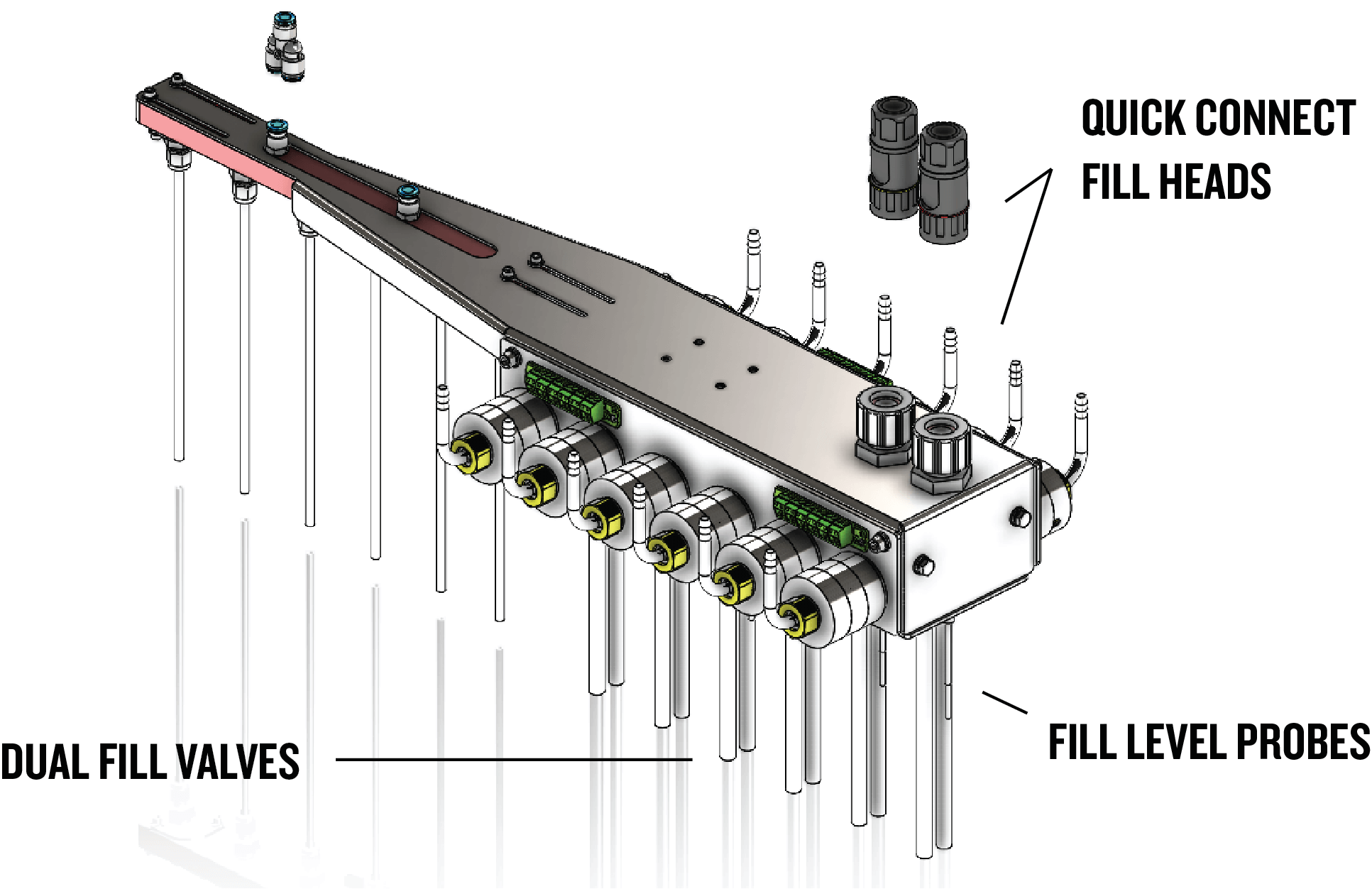

AT THE FILLING MANIFOLD

Dual Fill Valves overcome slower cycle times to achieve that laminar flow without sacrificing total system speed. Using two narrow fill tubes as opposed to one large diameter tube creates packaging-side precision and control and the restriction curbs CO2 breakout at the filler.

KEY TAKEAWAYS

THERE IS A MIS-MATCH BETWEEN PERCEPTION OF CARBONATION AND IN-CAN DATA

The perception of fizzy beverages is that the carbonation level is much higher than the reality of what’s in-can. Craft beverages don't need to exceed CO2 volumes in low-3 levels, with the bulk of many successful products carbed surprisingly low in the mid-2 volume range.

CARBONATION HAS A THRESHOLD OF TASTE PERCEPTION

Taste is logarithmic and there is a threshold of perception beyond which increasing carbonation is not detectable.

THERE IS A PRACTICAL LIMIT ON STATIC CARBONATION IN-TANK

There's a practical physical limit on static carbonation on a 15psi brite tank that's comparable to the low-3 volume CO2 limits of in-line atmospheric filling systems.

IN-LINE ATMOSPHERIC FILLING CAN SUCCESSFULLY PACKAGE HIGHER CARB BEVERAGES

In-line atmospheric packaging processes can successfully package up to 3.3 with low product loss, challenging the status quo that higher carbonation beverages require counter pressure filling processes.

Want access to more Data Labs?