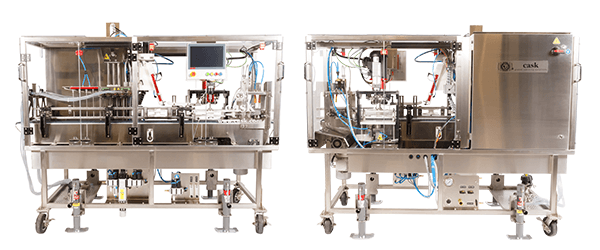

For Craft Coast Canning, one ACS Mobile canning system wasn't enough to expand their fleet. Shortly after becoming the first to purchase Cask’s new Automated Canning System Mobile, Craft Coast bought a second one. It’s the sixth Cask system for Craft Coast, which serves beverage makers in the Maritimes region of Eastern Canada.

“The commissioning of the ACS Mobile was really easy, and it runs the most efficiently of any system out there,” says co-founder Melinda Ponting-Moore, who founded the company with her husband, James Ponting, in 2017. “It’s reliable, we’re consistently getting 48-50 cans per minute, and it’s just what we need in its ability to package any beverage type customers bring our way.”

Craft Coast has worked with over 100 beverage brands since launching and about half of what the company packages today is non-beer. The list of un-hopped beverages includes wine, lemonade, coffee and a new “dog beer” made from a beef broth. “It has fatty particles in it,” Ponting-Moore notes, “but with the ACS Mobile system’s food-grade features and CIP/SIP process it’s very easy to clean the system after we package that product.”

The ACS Mobile’s stainless steel fill heads and cleaning capabilities enabled Craft Coast to receive their food-grade rating from the Canadian Food Inspection Agency, and a Certified Organic status since the system can be cleaned with products that uphold organic standards.

CO-PACKING

While Craft Coast’s second ACS Mobile will go on the road when it arrives this summer, their first ACS Mobile is actually in a residency of sorts at a customer that cans cider and spirits-based RTD beverages. The system allows Craft Coast to provide co-packing services and R&D for that client, and take advantage of the ACS Mobile’s state-of-the-art features.

“What makes us different,” Ponting says, “is that we see ourselves as partners to our customers, not just a canning service.” In addition to its packaging services, Craft Coast can provide new-product development help and branding and graphics expertise, and carry out extensive lab testing on the wide array of beverages it cans for its customers. “We love the low dissolved oxygen levels we get with Cask equipment,” Ponting notes.

That “from plan to can” approach and Cask equipment has helped Craft Coast enjoy impressive annual growth - 100% each year since its start - and become the go-to resource for maximum-quality canned beverages in its region.

“Our mission,” Ponting Moore says, “is to act as an accelerator for the craft beverage makers in the Maritimes, to make them successful and create a beverage community with a reputation for the highest quality possible.”

If its full-service methods mean Craft Coast’s clients are quicker to move into their own canning equipment, so be it. “They will outgrow us and that’s okay,” Ponting-Moore says. “We welcome it. Because we know we’ll be able to help them develop the best in-house packaging program and work with them down the line.”

MOBILE CANNING

When its second ACS Mobile hits the highway in a few months, it will be used for canning beverages (some of them Nitrogen-dosed) going into slim, sleek and standard cans, since the changeover between can sizes on the ACS Mobile is so fast and simple.

The incredibly compact footprint of the ACS Mobile (just under 88 inches in length) means the Craft Coast team can fit the system into smaller production spaces and enjoy a critical benefit for mobile canners: the ability to fit a few more pallets of cans in its trucks.

“When we first looked at canning systems,” Ponting notes, “Cask was the only canning system manufacturer that emphasized the quality of the packaged product, instead of just pitching the plug-and-play nature of the machine or some other feature. For us it will always come down to the quality of the packaged product. That’s why we have six Cask machines and steer people to Cask, because we know their systems are the best.”