2017 Year in Rebrew, er, Review

Before 2017 disappears in our rear-view mirror, we want to celebrate the past 12 months and fill you in on our cantastic efforts. Last year we passed the 850 systems mark and expanded our client country list to 46 nations. We welcomed micro-canning pioneers in Hong Kong, Italy, Hungary, Uruguay, Russia and other faraway and now happily canning lands. The revolutionary bottle-smashing effort we launched 18 years ago — with a tabletop, one-can-at-a-time machine — continues to roll across the world, and 2017 required quite an unusually high number of “Are we dreaming?” pinches. Meanwhile the aluminum can that was so reviled before we invented micro-canning has become the package of choice for discerning beer nuts, cider lovers, kombucha heads and cold-brew coffee fiends across the globe.

More People, More Power

To meet this uncanny demand and maintain Grade-A customer service, we expanded our staff by nearly 20 percent. That boost included a doubling of our Service & Support team, so that we continue to be properly resourced for our customers both new and old. We also added savvy new sales people (and are hiring more this year) to speed up our efforts in helping more craft beverage producers get their treasured creations into cans. Lastly, micro-canning legend Bill Rose has retired from Cask. After over a decade of making beer-industry friends and helping US brewers get their beer into cans, Bill has moved on to — literally — greener pastures. You can now find him frequenting golf courses in and around Phoenix, Arizona. Neil Love has assumed Bill’s lofty responsibility as our head of US sales, stay tuned for more updates from our sales team in the near future.

Beer & Other Life-Enhancing Beverages

While our focus has always been craft brewers, 2017 saw us expand our client list into more beverages than ever before. Our first kombucha maker (Happy Belly Kombucha in Alberta, Canada) put us in a refreshing new segment, and we helped cold-brew coffee makers such as Toronto’s Pilot Coffee Roasters, and Colorado’s Native Jack, catch the can buzz for the first time. Glen Edith Coffee Roasters (Rochester, NY), Topeca Coffee Roasters (Tulsa, OK) and Byron Beverage (Australia) also joined our roster of java canners.

New Year, New Gear

Our 2017 expansion into these non-beer niches was powered in part by the debut of our latest and greatest machine, the Micro-Automated Canning System (mACS), created by our dedicated Engineering & New Product Development team. A wiz-bang creation we’re especially proud of, the mACS was our response to numerous customer requests for a smaller machine with stellar features and the ability to easily can other drinks. How did we make it happen? By combining the best automated features of our various machines with novel package-size flexibility, all in one compact, mobile and affordable machine.

Did you know you can dial in fill settings on each individual fill head on the mACS? Operators of inline canning systems will know just how valuable this new features is!

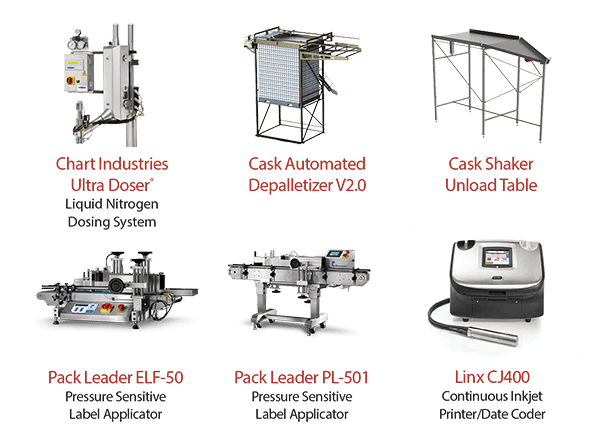

The mACS fills and seams cans of varying heights and body diameters, with changeover between different can sizes requiring less than 30 minutes. The mACS has new features (hello, electric cam-driven seamer) and a conveyor-belt can feeder that can be tricked out with such components as an automated depalletizer, nitro-doser, inline date coder, pressure-sensitive labeler, shrink-sleever and more.  Dead Armadillo Craft Brewing (Tulsa, Oklahoma) was one of our first mACS customers, the inventive brewery added a liquid nitrogen doser to the machine to expand beyond beer. “After many months of R&D,” says Todd Phillips, Dead Armadillo’s Director of Operations, “we’re entering the nitro cold-brewed coffee market with some friends at a local coffee roaster. It’s a brave new world for us that wouldn’t have been possible without Cask.”

Dead Armadillo Craft Brewing (Tulsa, Oklahoma) was one of our first mACS customers, the inventive brewery added a liquid nitrogen doser to the machine to expand beyond beer. “After many months of R&D,” says Todd Phillips, Dead Armadillo’s Director of Operations, “we’re entering the nitro cold-brewed coffee market with some friends at a local coffee roaster. It’s a brave new world for us that wouldn’t have been possible without Cask.”

“With the mACS,” says Cask founder Peter Love, “our customers get highly efficient filling and the ability to create new revenue streams and beverages. They can quickly shift to new can sizes for current products, or jump from beer and cider to soft drinks and uncarbonated beverages such as cold brew coffee, wine and energy drinks.”

So there’s a tip of our aluminum hat to 2017. Thank you all for helping us have our best year ever as we break the glass ceiling and help more craft beverage makers achieve their own uncanny success.