TOTAL COST PER CAN

As a beverage maker, you pour your time and passion into your product. While aluminum can supply can seem like a necessary evil, the right Can Program can really make or break your business.

Dramatic? Maybe. True? Definitely.

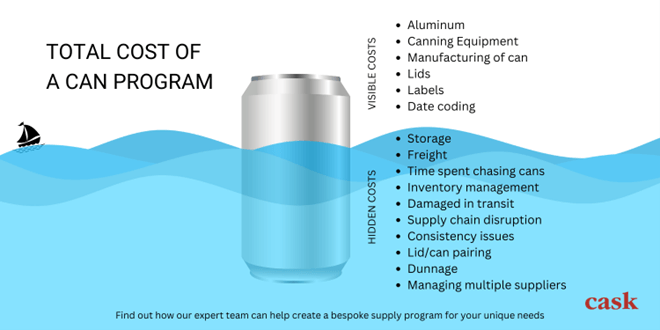

How can you approach cans in a way that allows you to focus on your craft? Understanding Total Cost Per Can (TCPC) metric helps create consistent and predictable profitability in your business.

The TCPC needs to encompass all costs related to getting your product into a can, and ultimately your customers’ hands. Partnering with a company that understands the big picture and all costs that need to be factored into a can is crucial.

HOW CAN CASK HELP?

1: Dedicated Account Management

It can take as many as 30 emails to procure a truckload of cans. Skeptical? Ask your team how many emails and calls they exchange with suppliers and logistic companies each time an order is submitted. And let’s not forget about submitting concrete forecasts for the upcoming months.

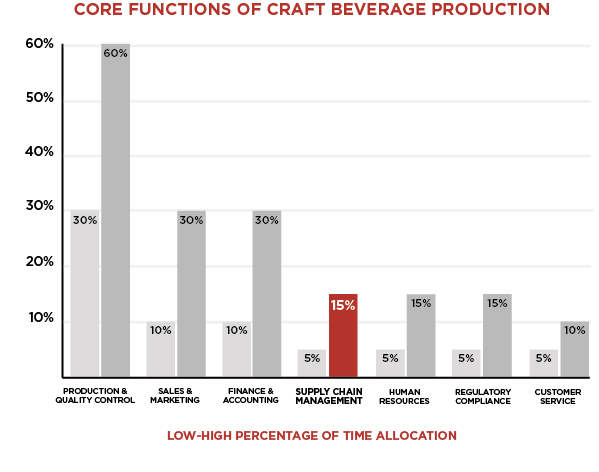

Quantified - say it takes 2 hours of emailing, calling and frustration to order and receive one truckload of cans. Multiply this by the number of orders you typically make in a year to determine your annual effort for procuring cans. In this scenario, 20 truckloads would take 40 hours of effort. Imagine you could reallocate that time in other core functions of your business?

Having a can supplier that offers account management removes this workload from your organization and significantly reduces the time, effort, and cost of procuring cans.

2: Proactive Communication of Market Changes

Have you ever received an invoice for a truckload of cans and noticed the amount was different from the last time you ordered? A lot of suppliers are subject to variable pricing and will either increase or decrease sell prices to adjust for fluctuation in their buy price. You may also be unpleasantly surprised by hidden fees and surcharges that were not communicated.

Another unwelcome event is receiving can ends from a different supplier without notice. Variable end supply leads to unpredictable results and poses a significant risk to your business.

A great partner will keep you informed of all changes and allow you to make strategic decisions for the benefit of your bottom line.

3: Collaborative Approach to Manage Inventory

During the Candemic, a lot of businesses took the strategic approach of holding cans in inventory in case further supply issues arose. If your company is looking to take on capital investment or must make an unexpectedly large purchase, it may be advantageous to deplete can inventory before placing new orders for cans. A great partner will work with you to reorganize orders in service of your company’s cash flow position and will not penalize you for not purchasing your projected volumes.

4: Consistency of Can Supply and Truckload Deliveries

While aluminum can supply has settled for the time being, it remains paramount for a can supplier to deliver on promises.

Inflation, unpredictability, supply issues and empty promises continue to add stress and complexity to navigating the craft landscape. Benchmarking freight with preferred carriers and following up on deliveries or any damage incurred and offering flexibility on over runs are table stakes when working with a partner that gives a shit. They understand the impact that delays or damage can have on your business, and they have the mindset of earning your business every single delivery.

5: Flexible Forecasting That Matches Your Workflow

Like managing inventory, forecasting can supply is a never-ending effort that you should not have to do alone. Especially with the seasonality in the beverage industry, there is a ton of value in working with a partner who intimately understands your business goals and works with you in a way that sets you up for success. A great partner will work with the changes in your forecasts, that inevitably happen throughout the year, and should never penalize you for not being 100% accurate in predicting the future.

1 Truck MOQs for Ball Printed cans is back!

Want to discuss getting into smaller volume Printed cans?

While price is certainly important when procuring a commodity like an aluminum can, it shouldn’t be the only consideration. By considering these five elements of TCPC, craft beverage companies can ensure that they are getting the best value for their money and that they are entering a partnership with people who want to see them win.