Cut water usage and capture massive time and cost savings with the Quick Change Rinse Inverter. New features include the first UV-C & Ionized Air treatment and 3D Printed Can Inverters that enable fast, tool-less can size changeover.

Improving sustainability means getting more from your packaging equipment.

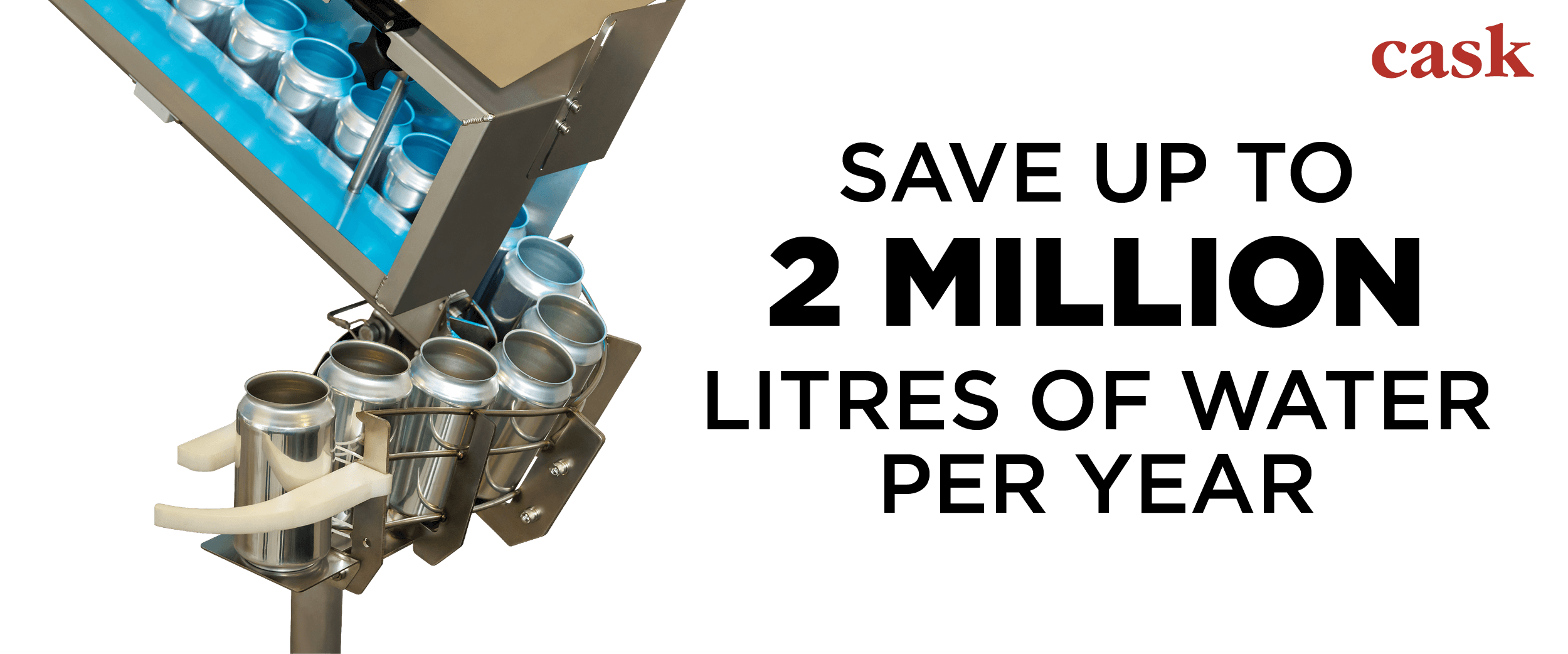

UV-C & IONIZED AIR TREATMENT

Craft beverage production can be water-intensive. As a partner in packaging Cask is innovating in service of helping craft beverage makers in their sustainability efforts.

BENEFITS

UV-C radiation effectively kills microorganisms and coupled with Ionized Air, this add-on solution cuts out water from the treatment process and reduces Dissolved Oxygen by eliminating oxygen-trapping rinse droplets.

WATER RESOURCES

A recent article from the Brewers Association highlights water scarcity as a looming threat for craft beverage. UV-C & Ionized Air treatment solutions help craft beverage makers future proof their businesses with water in mind.

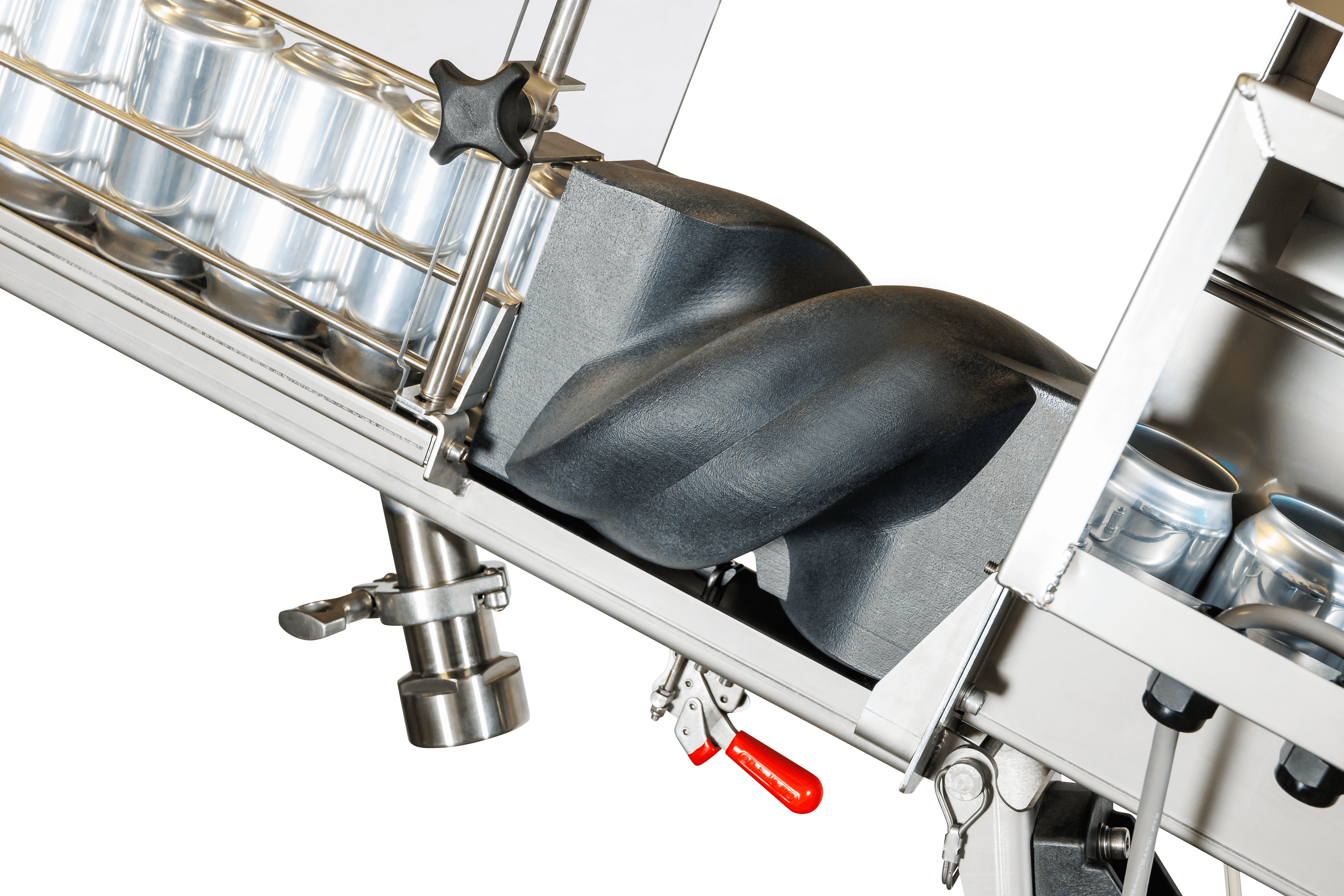

3D PRINTED CAN INVERTER

Launching new product styles is one of the Top 3 ways Cask customers indicated they intend to grow over the next 1-3 years. More than ever craft beverage makers are making use of multiple can sizes to get their products to market. The specially manufactured Nylon 3D Printed Can Inverters enable massive time and cost savings with tool-less can size changeovers. Convert to any can format within seconds without having to change out your entire rinse cage.

NYLON 12 BENEFITS

The Nylon 3D Printed Can Inverters are vapor finished and yield benefits for craft beverage makers:

- No degradation from caustic solutions

- Stable and durable over time

- Optimal for humid climates

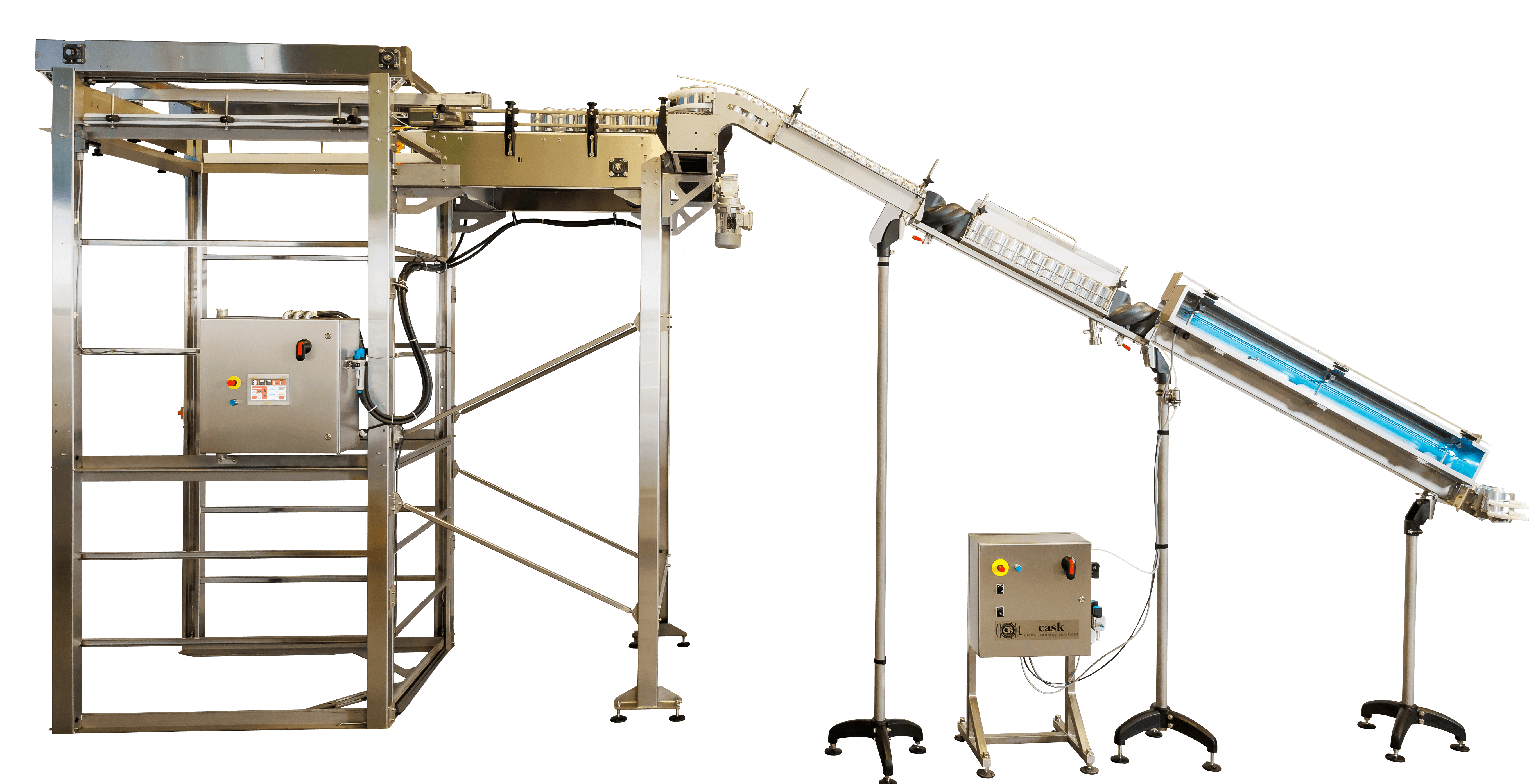

TURNKEY INFEED SOLUTION

Cask's new Quick Change Rinse Inverter with UV-C & Ionized Air add-ons pairs with the Automated Depalletizer for a turnkey infeed solution. Connect with Cask to learn more about configuring the right infeed solution to any of our Automated Canning Systems.