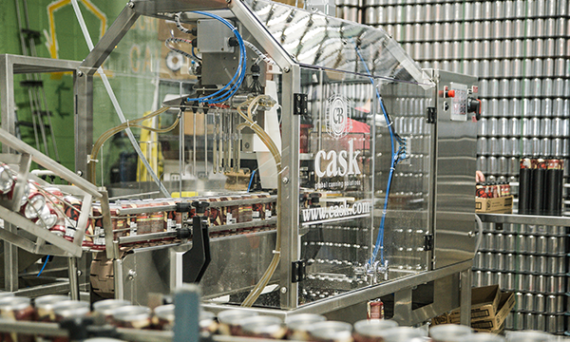

Cask released a new system designed especially for mobile canners. The ACS Mobile (Automatic Canning System) is a highly agile version of Cask’s legendary ACS. It delivers the speed and state-of-the-art automation of the ACS on a frame that is just under 88 inches.

It’s a timely new system, as large numbers of non-packaging breweries have had to shift to packaged beer to survive the pandemic.

“Our goal with the ACS Mobile,” says Co-owner, Neil Love, “was to create the ultimate canning system for mobile canners and their customers. It gives mobile canners facing increased demand the best array of tools for efficiently canning distribution-ready craft beverages. For brewers turning to mobile canning for help during the pandemic, they get beers with extremely low dissolved oxygen, with minimal product waste or low fills.”

“The ACS Mobile,” Love adds, “puts our industry leading fill technology on an immensely compact system that packages an array of beverages and can sizes, and includes a weigh scale, auto-reject, and the other sophisticated automation that comes on a full-size Cask canning system.”

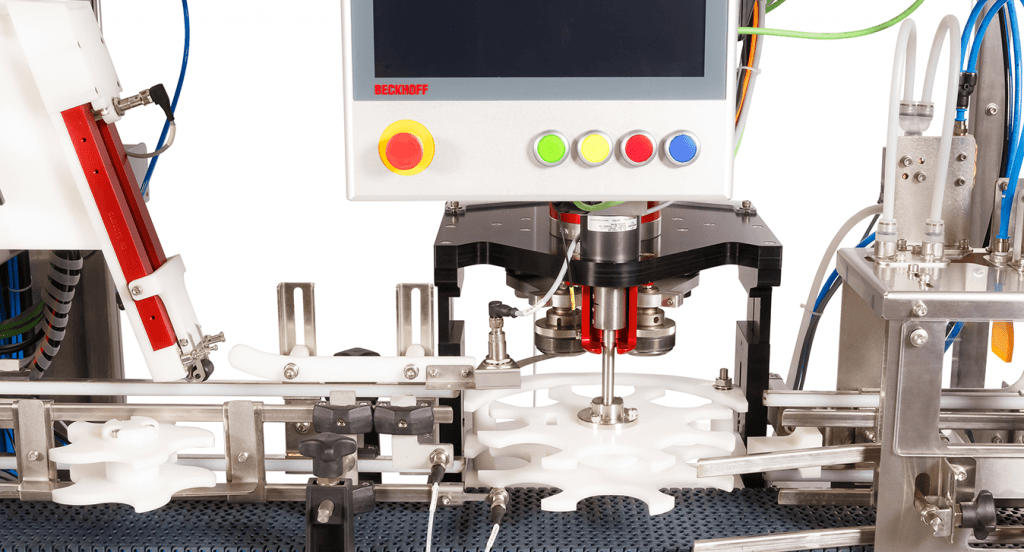

Cask Engineer Leighton McColl led the project (dubbed “Every Inch Counts”) to design and build the ACS Mobile. His research included input from Cask mobile canners on what their dream mobile system would include.

Olof Haggstrom, whose Sweden-based Can Man mobile service mobilizes six Cask systems, provided insight that shaped the system’s reinforced and fully enclosed frame, that fits on the lift gates of standard North American and European trucks.

“Olof,” McColl says, “told us that a frame longer than 88 inches required him to use a larger truck that cost more money and required a more demanding class of driver’s license. That’s why the ACS Mobile is 87.5 inches long.”

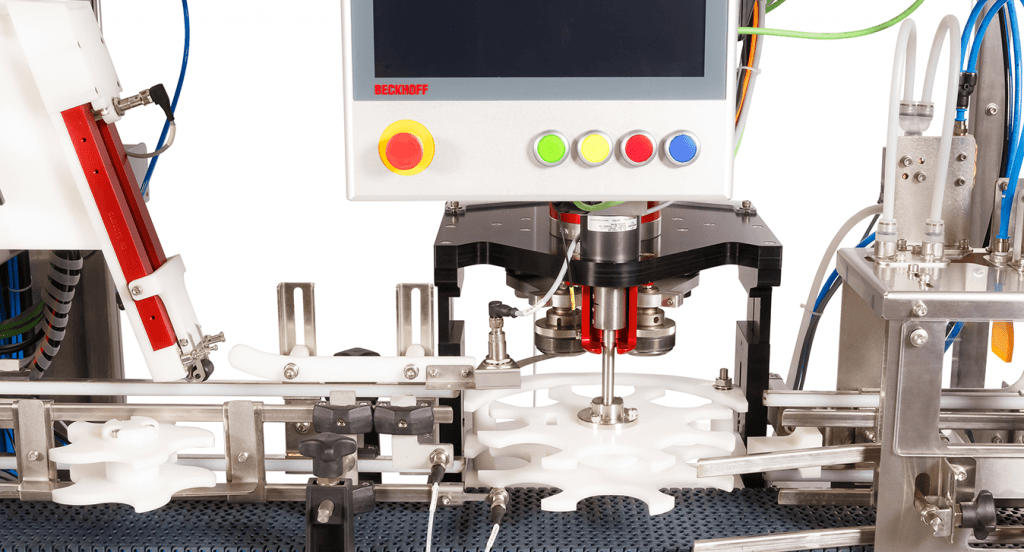

The ACS Mobile fills all Slim/Sleek/Standard cans up to 19.2 oz. and the system’s floating can-indexing wheel makes for the fastest available changeover between can sizes. The system’s stainless-steel fill heads are compatible with beer, wine, kombucha, cider, mead and other beverage types, and can handle high-strength CIP measures to ensure no transfer of flavor or contamination between beverages.

The system also has an easy to operate Windows 10-based operating program that enables a fast set up and easy operation.

McColl was a Cask canning system installer for three years prior to moving to his engineer role. His experience was helpful for boosting the mobile-minded features in the new mobile system.

“Doing installations,” he notes, “showed me just how tight the spaces are that our customers work in. So they need a system with a very small footprint that will still give them the speed, automation and maximum shelf-life and quality needed to grow their businesses. That’s what we’ve given them with the ACS Mobile.”

See the ACS Mobile > (more…)

Read More